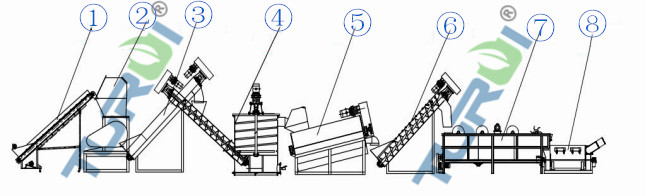

PP PE bottle washing line

1: Waste PET plastic recycling is the use of waste plastic PET mineral water bottle tablets recycling cleaning granulation line equipment after crushing, cleaning, drying, heating plasticizing, stretching, cooling, granulation, processing, production of PET powder, Made of PET related products. However, PET bottles can only be used once, which reduces the plasticity of PET plastics, so it is necessary to develop a new PET plastic recycling machine.

1: Waste PET plastic recycling is the use of waste plastic PET mineral water bottle tablets recycling cleaning granulation line equipment after crushing, cleaning, drying, heating plasticizing, stretching, cooling, granulation, processing, production of PET powder, Made of PET related products. However, PET bottles can only be used once, which reduces the plasticity of PET plastics, so it is necessary to develop a new PET plastic recycling machine.

2: Waste plastic PET mineral water bottle recovery and cleaning line equipment is a sorting, stripping, crushing, cleaning, dehydrating, drying and recycling of PET (polyester) plastics such as waste mineral water bottles, coke bottles and PET plastic bottles. It is mainly a production line for pulverizing, cleaning, dehydrating and drying PET bottles. It is a fully automatic production line. Waste plastic PET bottle water bottle recycling cleaning line equipment can be used PET bottles, after crushing, cleaning, drying, can meet the requirements of the net sheet material, can be directly drawn (granulation) for PET related products. Mechanical equipment is highly automated. During the cleaning process, we can complete the crushing, washing and dewatering process of the entire bottle.

3: The production line is developed through the introduction and absorption of advanced concepts and technologies of the same industry in the world, combined with the needs of today's development and the secondary application of waste plastics, which can meet the environmental protection requirements for waste plastics recycling at home and abroad.

4: According to different materials and production requirements, we have different crushers and dewatering equipment

5: Our company specializes in the production of PE/PP and floating material recovery cleaning line, PET and sinking material recovery cleaning line film recycling cleaning line and granulation granulation equipment. 1. High-efficiency, water-saving equipment, the machine features: beautiful appearance, low energy consumption, high output, practical and reliable. The new rinsing device can be used with the washing, greatly improving the production efficiency, and the cleanness of the washing material is pure, reaching the requirements of the first-level net film.

1. High-efficiency, water-saving equipment, the machine features: beautiful appearance, low energy consumption, high output, practical and reliable. The new rinsing device can be used with the washing, greatly improving the production efficiency, and the cleanness of the washing material is pure, reaching the requirements of the first-level net film.

2. After the PET bottle recycling cleaning line is installed, check the fastening condition of each fastener. If it is loose, it should be tightened. Also check that the belt tightness is appropriate.

3. PET bottle recycling cleaning line and power unit should be installed firmly. Ensure that the power pulley (diesel or electric motor) and the PET bottle recovery washing line pulley groove are in the same plane of rotation.

4. Before starting the PET bottle recycling cleaning line, first turn the rotor by hand to check whether the teeth, tool holder and flywheel are flexible and reliable. There is no collision in the crushing chamber. Whether the rotation direction of the rotor is consistent with the direction indicated by the machine arrow, the power machine And plastic, film recycling cleaning line lubrication is good.

5. Do not change the pulleys casually, in case the rotation speed is too high, causing the explosion chamber to explode, or the rotation speed is too low, which affects the working efficiency of the plastic and PET bottles.

6, work should pay attention to the operation of plastic and film recycling cleaning line at all times, firstly, the feeding should be uniform to prevent the crushing material room; secondly, do not overload the work for a long time. If any vibration, noise, bearing and body temperature are too high, and the material is sprayed outward, stop the machine immediately and check it out.

7. After the PET bottle recycling cleaning line is started, it should be kept idling for 2~3min. After no abnormal phenomenon, it will be fed again.

1. Granulator: film, woven bag, ton bag, fishing net, sheet, single and double-stage granulation line, single and double screw granulation line

1. Granulator: film, woven bag, ton bag, fishing net, sheet, single and double-stage granulation line, single and double screw granulation line

2, Washing line: PP, PE, PET, film, bottle, sheet washing line;

3. Extruder: single screw extruder, conical twin screw extruder, parallel twin screw extruder;

4. Water ring dicing die, film dewatering and extruding machine, squeezing and granulating machine, centrifugal dewatering machine, pelletizing machine, shredder, crusher, plastic auxiliary machinery and other equipment.